Protection and Sorting: Boosting Safety with X-ray Tech

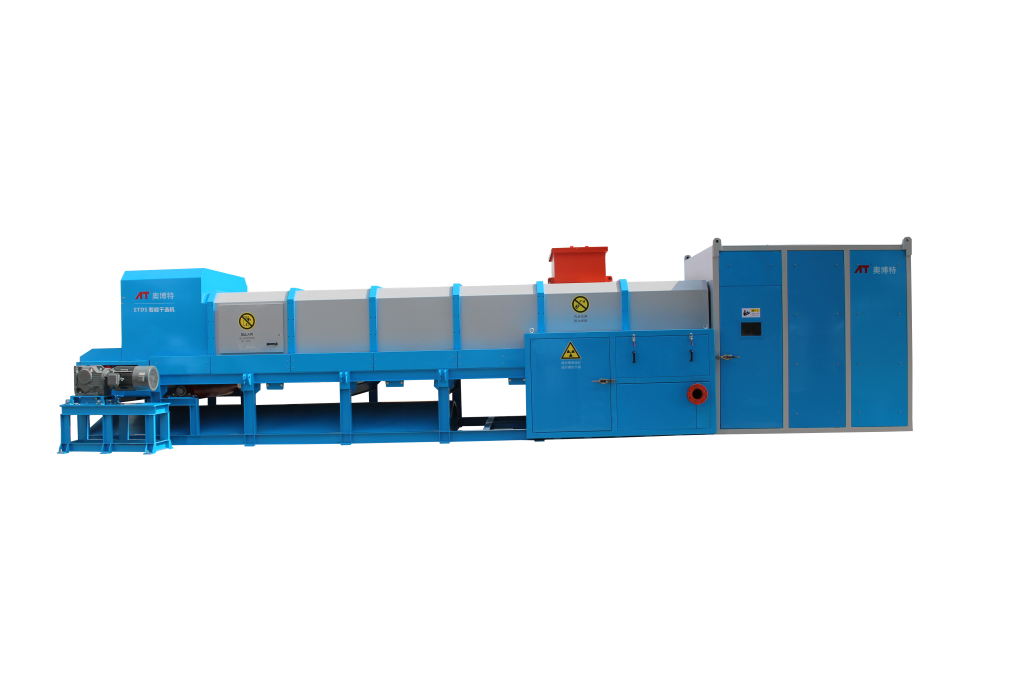

In an era in which security and efficiency are paramount, X-ray sorting technology is emerging as a crucial tool across various industries. The integration of X-ray intelligent sorting equipment not only enhances the accuracy of material separation but also significantly improves safety protocols. By using sophisticated imaging techniques, these machines can detect and categorize materials based on density and composition, making them essential in sectors like recycling, mining, and waste management.

The emergence of X-ray intelligent sorting machines marks a notable shift towards smarter processing solutions. These innovative systems leverage sophisticated algorithms and real-time analysis to improve mineral sorting processes, guaranteeing only the best materials are gathered. As industries persist to focus on safety and operational efficiency, the implementation of X-ray sorting technology is becoming a crucial strategy to reduce risks and maximize productivity.

Comprehending X-ray Methods in Separation

X-ray techniques has changed the sorting process across numerous industries by presenting a non-intrusive method to detect and differentiate materials based on their weight and structure. This technology employs high-energy X-rays to pass through materials, allowing for comprehensive analysis without the need for physical alterations. The result is a quick and effective sorting process that boosts both security and operational efficiency.

X-ray intelligent sorting equipment is designed to instantly differentiate between valuable materials and contaminants. By evaluating the unique characteristics of different substances, these machines can precisely sort minerals, metals, and other components. This feature not only optimizes operations but also significantly reduces pollution and increases the overall standard of the output material, making it an critical asset in industries such as mining and recycling.

The implementation of X-ray intelligent sorting machines into existing workflows can revolutionize traditional processes into advanced operations. These systems can adapt to varying material types and sorting criteria, providing adaptability and precision. As industries focus on sustainability and resource recovery, X-ray technology plays a vital role in achieving higher efficiency and lower environmental consequences, establishing it as a key player in the future of material sorting.

Applications of X-ray Automated Separation Equipment

x-ray smart separation machines has transformed various fields by enhancing the performance and accuracy of resource separation. In the extraction sector, these devices are utilized to recognize and sort minerals based on their weight and characteristics. This technology enables workers to distinguish valuable ores from waste materials, optimizing resource extraction while minimizing environmental impact. By enhancing the separation process, mining companies can greatly increase output and reduce expenses.

In the recycling industry, x-ray smart separation equipment play a vital role in recycling reuseable resources. They are adept at distinguishing between different types of synthetics, metal types, and other items, ensuring that the recycling process is both effective and dynamic. By automatically sorting materials with high accuracy, these systems prevent contamination of recyclables, leading to superior end products. This capability not only improves recycling rates but also contributes to sustainability efforts by promoting the reuse culture.

Moreover, X-ray intelligent sorting equipment is being used in various agriculture applications. Within this industry, the equipment is used to inspect and categorize food products, ensuring health and quality standards are met. The competence to detect foreign objects, such as pieces of metal or foreign materials, helps to secure the food supply chain. By maintaining stringent safety standards, food manufacturers can protect consumers while enhancing their brand image in a dynamic market.

Benefits of Xray Sorting Equipment in Safety and Productivity

X Ray automated scanning machines significantly improves protection by providing clear imaging of objects without the need for the necessity for physical scrutiny. This capability allows safety personnel to promptly identify possible hazards and forbidden objects, ensuring a more secure environment in a diverse of contexts. By utilizing advanced scanning methods, these devices can tell apart between different materials, enhancing the productivity of security screenings in aviation centers, customs areas, and community gatherings.

In addition to strengthening protection, Xray intelligent classification systems boost overall operational effectiveness. They can process substantial quantities of items swiftly, diminishing delays and ensuring a uninterrupted flow of goods or individuals. This efficiency is essential in crowded locations where delays can lead to irritation and security vulnerabilities. The adoption of these machines allows for streamlined processes, freeing up staff to focus on more complex security responsibilities.

Moreover, the adaptability of mineral scanning machines showcases the value of X-ray processes beyond security. In sectors such as extraction, X Ray sorting allows the precise distinction of precious materials from scrap substances, optimizing resource retrieval. This not only enhances output and minimizes ecological impact but also supports eco-friendly methods by reducing the requirement for excess processing. Hence, X Ray sorting methods serves a dual role of improving security and improving effectiveness across multiple industries.